About My Skills and Background

I am a dedicated professional with a strong background in laboratory automation, process optimization, and user experience design. Over the years, I have built upon these skills to provide solutions across various laboratory applications, always striving for maximum efficiency and quality of the end product. Continue down this page to follow my career opportunities, and how they have shaped the person I am today.

My Career Story so Far

Below is a step by step guide to my experiences so far. They outline the projects I worked on, the knowledge I gained, and the skills I developed at each stage.

Education

I studied Pharmaceutical Science at the University of Rhode Island College of Pharmacy. I was fortunate enough to be in by a brand new, state of the art laboratory and classroom space, as well as surrounded by enthusiastic and knowledgeable teachers. Pictured to the left is my first PI, Dr. Angela Slitt, who is now the Chairperson for the Department of Biomedical and Pharmaceutical Sciences. While I worked in her lab, I was under her tutelage, as well as taught by the other graduate researchers in the lab. I learned about basic lab techniques and etiquette. As a toxicology lab, much of the focus was on dose management in mouse models, protein expression in their tissues, and metabolic markers in their life. One of the biggest lessons I learned in Dr. Slitts lab was that In-Vivo work was not for me. I thoroughly enjoyed the lab work and data analysis end, but handling animals and performing tissue collection made me very uneasy. A critical lesson to learn for the direction my career would follow.

Academic

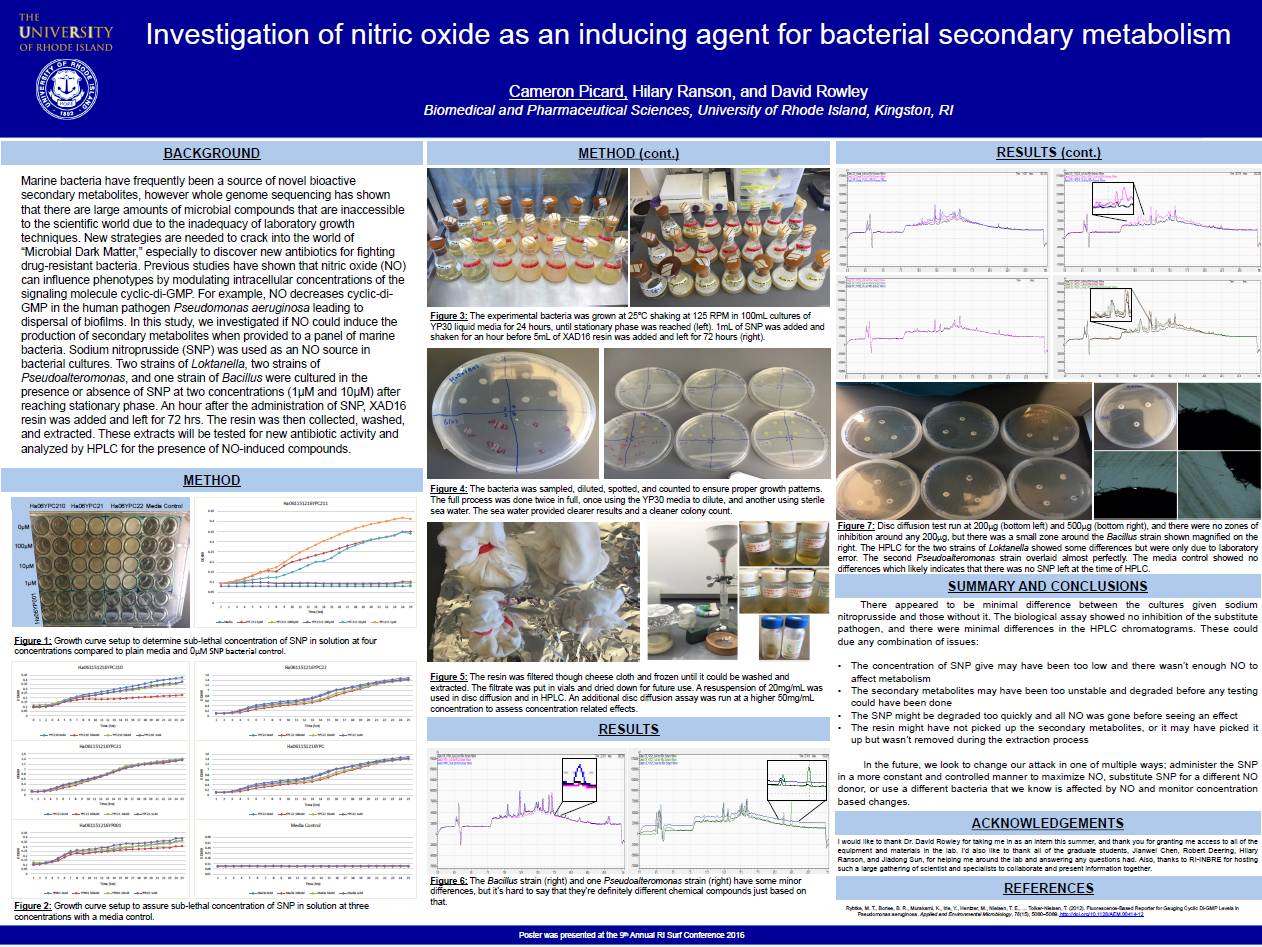

Through my studies, I discovered a proclivity for microbiology as it relates to pharmaceutical science. The idea of living organisms on a micro scale, waging war on our bodies in the pursuit of their own survivorship, while we design new ways to attack their evolved mechanisms, is all massively exciting. This lead me to add a biology minor, with a microbiology focus to my education. I asked to join Dr. David Rowley’s lab, who worked on a combination of natural product discovery projects, and microbiological culturing studies. I worked closely with Hilary Ranson, a talented graduate student in Dr. Rowley’s lab, who taught me some finer laboratory skills, like maintaining an aseptic environment, proper experimental design, and how to analyze and present data. As a summer intern in the lab, she helped me execute an experiment to uncover biologically active metabolites through oxidative stress, the results of which can be found in the poster to the right. The poster was written for the 2016 Rhode Island SURF Conference, and presented by myself as a summer internship capstone. I’m incredibly grateful for the time I spent in Dr. Rowley’s lab.

Clinical

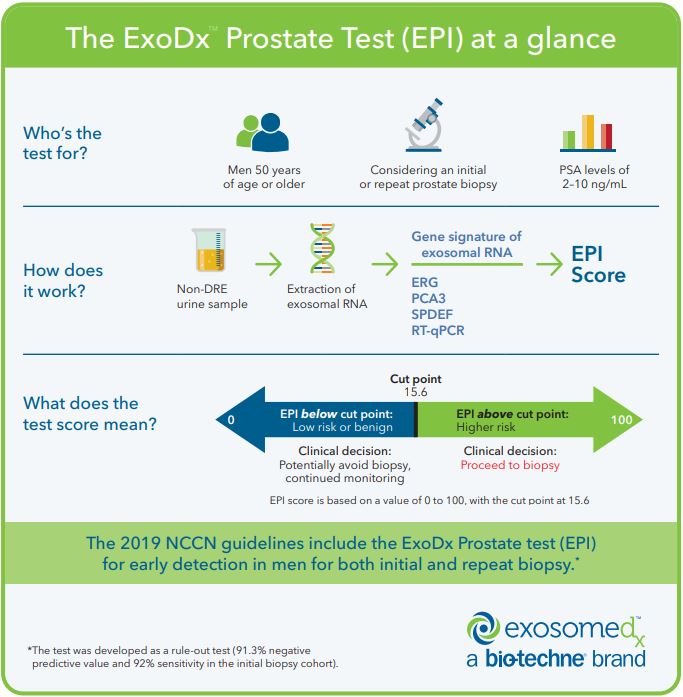

My first job out of college was with a small startup diagnostic company called ExosomeDx. I was hired as a contract employee through Apex Life Sciences recruiting, and worked in the clinical lab performing their only exosome based prostate cancer assay at that time. I was eventually offered a full time position as a clinical technologist, shortly after the company was bought by Bio-Techne; a large supplier of biologics, expanding into the clinical diagnostics sector. Being a startup organization, I had to wear many hats outside of just my lab duties. I was also involved in QC processes, product kitting, accessioning and sample preparation, and other odds and ends tasks that needed to be done to keep thing running smoothly. This role was a critical step in my development of good lab practices, proper documentation, and understanding the many ways in which industry differs from academia. As an up and coming CLIA and CAP accredited laboratory, much focus was put on both following and improving procedures. I credit my time in the clinical lab for my proficiency at the bench, since it was paramount that every sample on any given day be treated exactly the same way. There was an opportunity to become a team lead, but I found that I wasn’t fond of the repetitive nature of clinical lab work. Luckily there was also a position opening up with the R&D department, which I was able to transfer into.

Research

My transition to the R&D team at ExosomeDx was my first exposure to laboratory automation. There was a Hamilton STAR Plus instrument that was a copy of an instrument at our sister site in Germany. Part of my role on the R&D team was getting the instrument up and running to perform the ExoDx Prostate Test like they had running in Europe. The other part of my role was doing development work on making the assay more automation friendly. While column based filtering is possible with some instruments, the more conventional extraction method uses magnetic beads. A method for exosomal extraction was already developed and was very robust. The nucleic acid extraction was less well defined, and was my responsibility to try and solve. We tackled this a number of different ways; using high throughput vacuum columns, tested a variety of bead vendors and chemistries, and a range of fully to semi automated processes. We were starting to make progress, but there were other projects that popped up that were more mission critical. The typically flawless columns used in the manual workflow started to fail randomly. This triggered a full blow route cause analysis that I led, due to my familiarity with the assay in my time as a clinician. I was also drawn into different contract projects for external parties, and some internal validation work for the ExoTRU kidney transplant rejection assay. At the end of my tenure, COVID was in full swing. It became my full time job adapting an existing method from Zymo for COVID testing to work on our instrument, and getting it prepped for validation. I departed before I could fully realize the fruits of my labor, however, I see this stage of my career as a real kicking off point for all of my work going forward. Had I not been exposed to and trained on the Hamilton, I would not know just how enjoyable laboratory automation work is, and how passionate I would be for pursing it further.

colorado

My girlfriend, now wife, made the decision to shake up our lifestyle and move out of New England to Colorado, joining a friend of ours who was enjoying the same move he made a couple of years earlier. In doing so, I joined ArcherDx after a recent acquisition by Invitae as an Assay Development Assocaite in Automation. This was an opportunity built of new experiences. New location, new platform working with Tecan Fluents, new application in the NGS space, new technology as an Apple based IT infrastructure, and of course a new team. I was mainly responsible for supporting the assay development scientists in the pursuit of automation friendly workflows. I ended up having to self-teach on the Tecan Fluent software due to limited access to training sessions a the end of COVID restrictions. Through many iterations and trial and error, I was able to develop a working library prep method, establish liquid handling best practices, and put together some documentation for SOP. Some corporate struggles led to a lot of restructuring and we were joined by a proper software engineer. While my method was functioning well, he was able to impart a lot of software knowledge onto me, and we worked together to define programming conventions and structure. This would allow us to create a modular code base that would be easily accessible to anyone jumping in, as well as quickly modifiable for internal or external use. As it turns out, there is a large install base of Tecan instruments in the field, but not many were being used regularly for NGS applications by our customers at the time. This led us to source a Hamilton STAR to try and reach more of our customers where they currently are.

End-to-End Automation

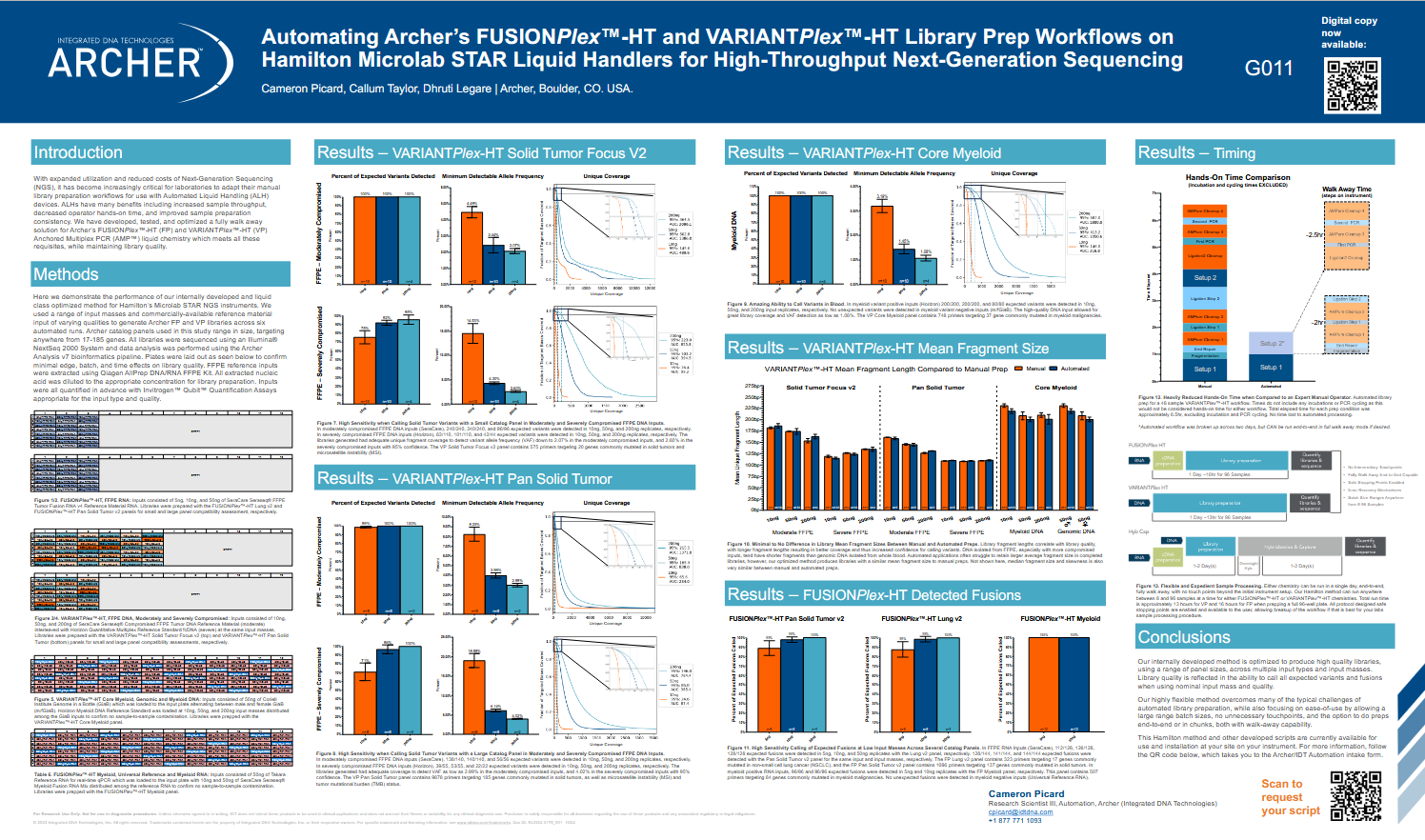

Part of our restructuring included a company spin out, where the Archer RUO NGS product was acquired by Integrated DNA Technologies, a stalwart in the oligo space looking to expand their NGS offerings. I became the sole programmer again, working exclusively with the newly acquired Hamilton, and performing the bench work associated with troubleshooting and validation. This became my proudest career accomplishment for the degree of success I saw and the timeline I was able to execute on. In a year, I built the method from scratch conforming to all of the same standards we established earlier, performed nearly all of the experiments to ensure performance was equivalent to an expert manual operator, designed and executed a large scale performance study, and put together a poster that was accepted at the AMP 2024 conference. The finer details can be seen in the poster to the right, but it was performing as well as an operator, able to be run end-to-end hands free, all without costing turn around time for sample prep. This project taught me a lot about understanding customer needs, designing a verification style experiment on a budget, and putting together a descriptive poster that drives home the main benefits our Hamilton method provides. Toward the end of my tenure with Archer, I was involved in generating a lot of marketing material and documentation around our automation friendly products, including cost-of-goods benefits, hands-on time analysis, and field training documents for both customers and applications specialists. I was also leading our internal training and usage efforts to get external perspective on the instruments usability.

Remote

I have recently left Archer and joined Hamilton as a remote Field Applications Specialist working out of my office in Colorado. I joined as an opportunity to get one level deeper with the automation vendor that I have enjoyed working with so much already. I now have access to so many additional tools and resources that were inaccessible to me as a customer. I’m also exposed to a wider array of automation applications and am developing skills in a new customer facing role. I have so far enjoyed being able to apply myself in so many different scientific areas, all while working hard to meet customer expectations whenever possible. I am looking forward to fostering deeper relationships with the current customers I serve, while also adding new customers, experiencing other complex workflows, and adding new talents to my automation tool belt.